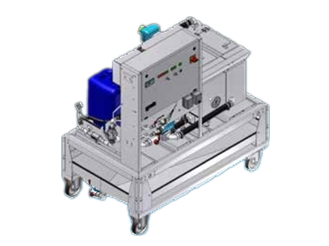

Moldclean mc 1-1 a mc 1-2

The Moldclean range is designed to clean dirty injection mould cooling channels and heat exchanger systems.

Maintenance for long-term reliability

Minerals in the circulating water can adhere to heat conductive surfaces, reducing heat transfer and causing corrosion. This leads to unstable processes, downtime and higher maintenance costs. With the moldclean range, deposits and corrosion can be effectively removed from cooling channels, reducing cooling times by up to 40% and increasing production efficiency.

KEY BENEFITS:

- Pulse cleaning with compressed air: for maximum cleaning efficiency

- Separate tanks: Stainless steel tanks for cleaning and neutralizing agents minimize chemical consumption

- Process monitoring: Permanent pH measurement and non-contact flow measurement ensure process control

- Easy to use: Clear and intuitive user interface

- Robust construction: Made of corrosion and chemical resistant stainless steel

- Mobility: stainless steel wheeled unit for easy handling

- Efficient cleaning: reversed flow direction and compressed air connection for draining the circuit

OTHER FEATURES:

- Integrated heating: to speed up the cleaning process

- Stainless steel drip tray: For safe collection of residual liquid

- Durable materials: All parts in contact with the media are made of corrosion-resistant materials

The moldclean range is the ideal choice for efficient maintenance of molds and heat exchanger systems. Automated cleaning reduces workload, increases productivity and contributes to long-term process reliability.